Dent & Buckle is announcing its integration with Mainblades, a company that specializes in drone-based aircraft inspections. This partnership will help airlines and maintenance teams save time and improve the accuracy of aircraft damage assessments.

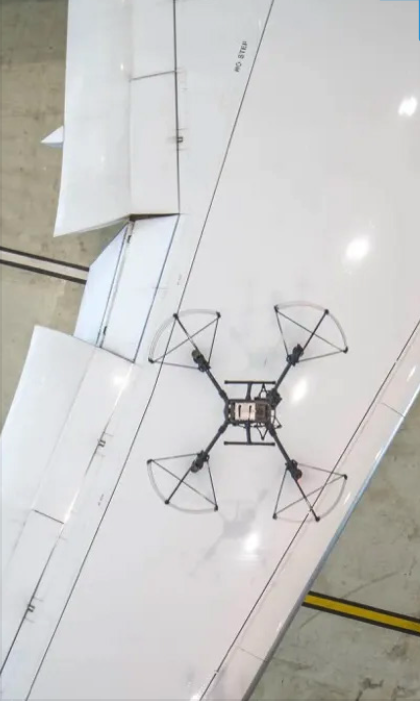

By combining Dent & Buckle’s damage reporting system with Mainblades’ drone inspection technology, aircraft inspections become faster, more precise, and easier to manage. During the autonomous flight, the drone collects data that is transmitted to a web-based platform where it’s reviewed by an inspector, optionally aided by ML models to speed up inspection.

The subsequently generated report with all the findings is seamlessly transferred to the Dent & Buckle defect records system, immediately creating a new dent & buckle chart item that is precisely located on their 3D models and easy to manage. This means:

- Faster, more safe and repeatable defect discovery: What used to take hours can now be completed in minutes.

- More accurate damage reports: Automated scans and precise data, combined with easy manual review and control ensure nothing is overlooked.

- Easier fleet management: Dent & Buckle damage records with all their documentation are instantly available for the entire fleet, improving oversight and decision-making.

We’re always looking for ways to make aircraft maintenance more efficient,”

said Paul Crabb, COO at Dent & Buckle. “Mainblades has been a fantastic integration partner, and our customers can now benefit from seamless defect data transfers between Mainblades and the Dent & Buckle defect management system.

The integration between Mainblades and Dent & Buckle demonstrates our commitment to building a digital ecosystem for automated inspections.’’

Explains Maurits Elzinga, Product Owner at Mainblades. “Collaborating closely with Dent & Buckle to bring this integration to life has been a rewarding experience and sets the stage for further expansion of the digital inspection ecosystem. The ability to easily exchange inspection data between platforms provides our customers with fast, consistent inspection results and a feature-rich environment for tracking aircraft conditions.